DRAWING 1:

You may take this process one step further by adding a 100 amp marine solenoid to the ground path as shown in Drawing 2. This further minimizes current loss by removing the foot switch(es) from the current path.

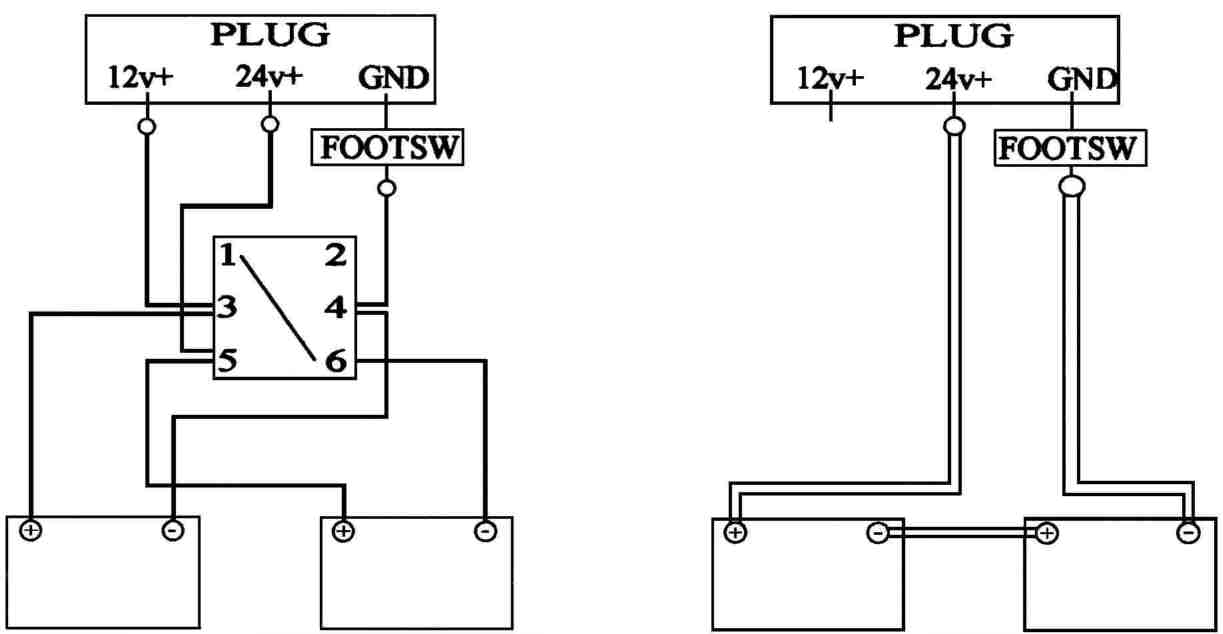

DRAWING 2:

Both of these mods

have been tested and, if done properly, will work well. There should

be an improvement in overall troll motor performance, particularly at sustained

high power settings.

The following is a list

of things to remember about batteries and charging:

1) If using lead-acid

batteries, check the water level regularly. I prefer to use distilled

water to replenish levels. Low maintenance batteries must be checked too.

2) Check battery mounts.

Assure that hold downs are tight.

3) Check that terminal

nuts are tight and free of corrosion.

4) Unplug troll motor

before charging.

5) Never connect or

disconnect a charger from a battery with the charger powered up. Arcing

can cause damage, especially to circuits attached to main battery. There is

also an explosion risk due to fuel fumes or hydrogen build-up

if the compartment has been closed.

6) Never leave an

external charger connected and unpowered. Many chargers

do not have a blocking diode and will discharge batteries.

copyright © by Ken Cook 1996, all rights reserved

Reprinted by permission of "Bass & Walleye Boats"